Compact and expandable system for product development and analysis – potential use in many industries

As part of an international university project, the Heinsberg-based specialist plant manufacturer, SM Coating, has designed and completed a new, innovative coating system for flexible product development.The laboratory system enables the testing of a wide variety of combinations of different web materials (e.g. film, textile, paper) and flat coatings.Therefore, the plant is interesting for many industries including, for example, the film, textile and adhesive industries.

The individual components for the machine were manufactured in our own factory in Heinsberg and thoroughly tested. Before delivery, the machine was assembled in the factory, extensively tested and then assembled to be ready for use at the customer’s site.

Compact, flexible and functional with little set-up effort

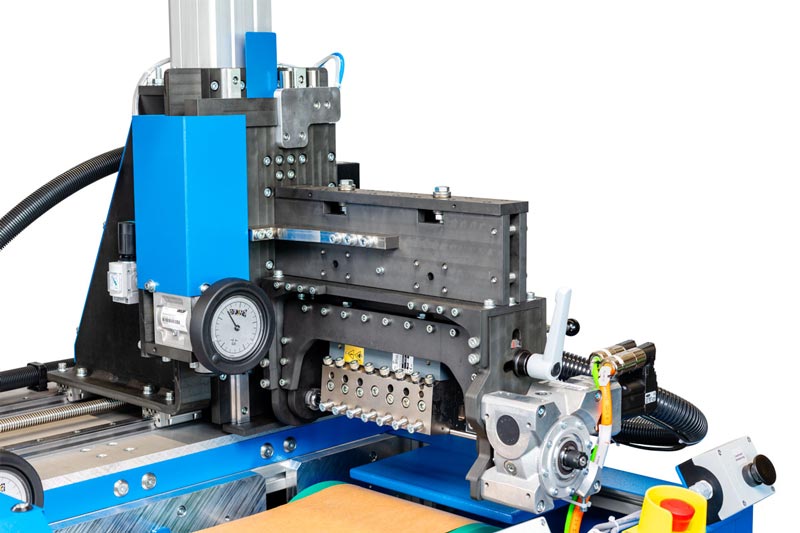

The compact laboratory system is flexible, functional and user-friendly. It enables fine dosing with a standard application-specific application weight of 8-60 g/m². Various hot melts but also, in part, other fluid media are thereby processed at wide viscosity (up to 50,000 MPas) and temperature (up to 200°C) ranges. Efficient, particularly uniform, low surface weight adhesive application takes place with a mutually exchangeable roller bar or wide slot nozzle. The head mount with movement options in four degrees of freedom ensures optimum alignment of the low-maintenance surface and roller bar nozzles. As a result, the uniformity of the order can also be fine-tuned. Short set-up times are guaranteed thanks to a quick-change system.

Minimal dead volume: ideal for testing microsamples

The minimum dead volume of the coating medium enables industrial companies to test with the smallest quantities. The tank unit of the system is interchangeable – for a quick change of the coating medium with a short set-up time. This enables efficient testing of the various product variants.

With the integrated software, all production data can be recorded, for example, web tensions, temperatures or pressures. During the later sample evaluation of the tests, this data can be exported and precisely classified. This serves to increase efficiency in product development with the following overarching goal of automatically generating derivations from this data for product optimisation.

The compact system can be easily expanded, for example, by a drying unit with infra-red radiation (IR) or with different test systems.